Our Philosophy

"To listen and take note of our clients needs and design specifications, generate ideas, solutions and execute them with a high level of detail and accuracy.

Since time is of the essence in today's manufacturing environment we strive to deliver on time every time."

ABOUT US

Based on the Gold Coast in Queensland, Australia, Austek Design was established in 2009 after working in the manufacturing industry for over two decades.

Having begun my career as an apprentice Tool & Die maker, I soon discovered I had a growing interest in the field of mechanical engineering design.

The natural progression from the drafting board was to use CAD as a design tool to produce designs that were accurate and time efficient.

The practical and theoretical knowledge gained from previous roles, gave me the confidence to provide design & drafting services based on sound principles and values.

services

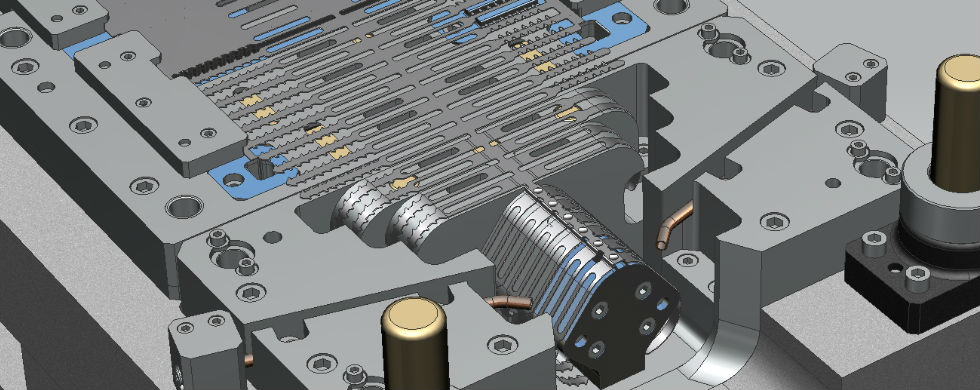

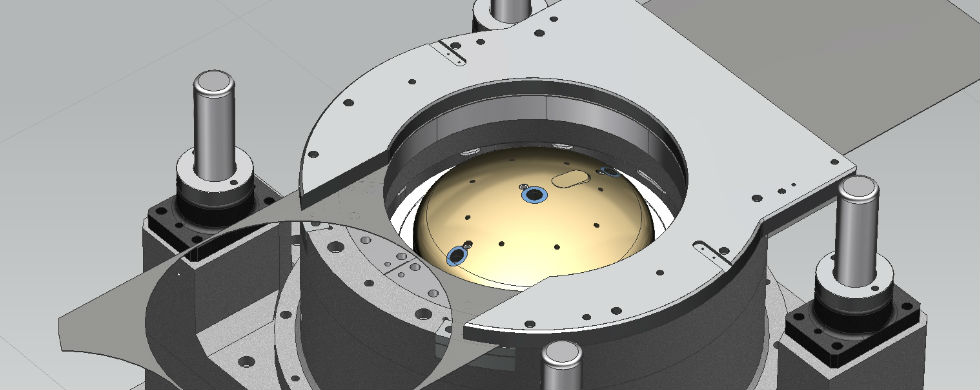

TOOL DESIGN

METAL STAMPING TOOLS | INJECTION MOULDS | JIGS & FIXTURE DESIGN

PRODUCT DEVELOPMENT

3D PRINTING | PROTOTYPING | DESIGN

CAD

3D SOLID & SURFACE MODELLING | FORMAT CONVERSIONS | DRAFTING

Articles

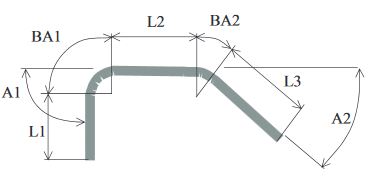

Bending is defined as the straining of the sheet metal around a straight edge.

Bend allowance:

This is the stretching length that occurs during bending. It must be accounted to determine the length of the blank.

Lb = ΣL+ΣBA

Lb is the length of the blank, L are the lengths of the straight parts of the blank, BA is the bend allowance.

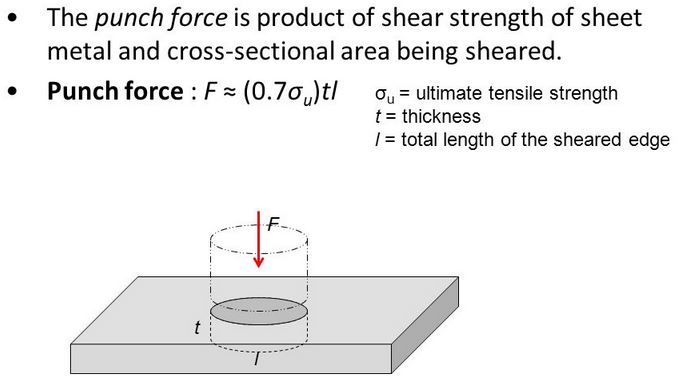

The maximum bending force is estimated as.

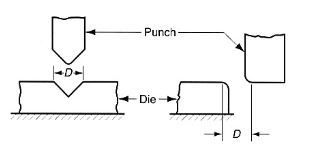

K x Lx UTS x T² ÷ D

K is the constant that depends on the bending process. K=1.33 for V-bending and K= 0.33 for edge bending.

L is the width of bending; UTS is the ultimate tensile strength of the material; T is the material thickness ; D or span is the die opening dimension as shown in the figure above.

Contact US

- austekdesign@gmail.com

- Gold Coast, Queensland, Australia